Oftentimes one of the most overlooked, yet overworked items on any high performance car is the rear end housing and suspension. Whether your interest lies in Drag Racing, Pro Touring or road racing; or even if your car is simply a daily driven performance car or street rod most enthusiasts simply put it together and forget it.

Yet the rigors of racing or performance driving can take its toll on the rear end housing, axles, differential and its related components. It is a good idea to inspect these items once a year especially if your car is raced on a regular basis.

Otherwise something catastrophic like this could happen to you! The next two photos show a broken and twisted axle.

Even if your axles look to be in good shape it is best to have them “magna-fluxed” to check for cracks along with a close visual inspection to look for “twisted splines”

After years of neglect, the rear end housing itself can become bent or twisted. When this occurs it can cause excessive wear on the axles, gear set and their related components. If the situation is neglected for too long; the only choice is to repair or even replace or upgrade the rear end housing.

Once the decision is made to replace a rear end housing critical measurements must be taken to insure that the new housing fits perfectly and all the suspension components will align properly once the new housing is ready to be installed. Ron at Ron Pircey Enterprises is well versed on the repair and fabrication required.

Leading manufacturer’s components are available through Ron Pircey Enterprises at competitive prices to make the repair or replacement process as “cost effective” as possible.

They include:

Strange Engineering and Dutchman Motorsports (Axles and rear end components)

Wilwood Engineering (Brakes and related parts)

Art Morrison Enterprises (Suspension and related components)

Once the measurements are determined and “double checked” the new housing and components can be selected.

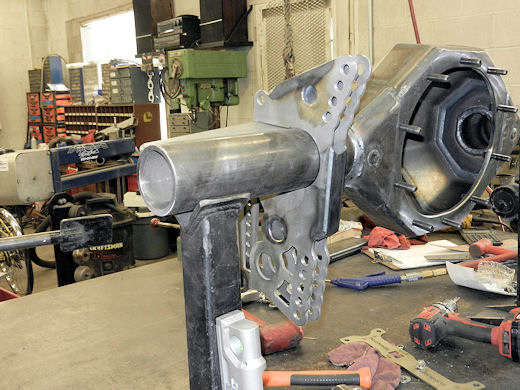

Next the new housing is setup on the jig table, leveled and squared so that it can be marked properly with the dimensions taken previously in order to locate all the required suspension mounting brackets.

Once the brackets locations are determined an alignment bar is placed through the housing so that it will ensure that the housing does not warp while all the brackets and housing ends are installed.

Then the lengthy process of welding everything into place gets underway. Care must be taken to insure that everything remains in its correct location during this step.

After the housing is completed you can begin the reassembly process. The housing shown up to this point was for a 9” Ford for a Drag Racing application and had 4-link, coilover, and wheelie bar mounts installed as part of the manufacture of the new rear end.

Ron Pircey Enterprises can narrow, repair and fabricate 8 ¾ Mopar, Dana 60, Dana 44 and even 12 Bolt GM housings to suit your needs.

March 21st, 2013

March 21st, 2013  admin

admin

Posted in

Posted in