Any drag racer will tell you, “Consistency wins races”. When Wayne Robinson began racing his ultra clean 65 Chevelle, it wasn’t long before he realized that traction with the high powered Big Block Chevrolet powerplant was an issue, and that the much needed “consistency” was a problem. Here is Wayne’s Chevelle before any modifications:

The “first generation Chevelle” was very limited on space for tires and the traction they provide. The 64-65 Chevelle in stock form can only fit around an 8-9” wide rear drag slicks. Which are easily overpowered by even a mild big block like the one in Wayne’s Chevelle.

Limited traction made it hard to “dial” the car and tire spin was a common occurrence. Wayne made the decision to install a narrowed rear frame, a 9” Ford Rear End Housing and ultra wide rear slicks to solve the “traction issue”. The plan was to include an 8 Point Roll Cage for safety.

Wayne chose Ron Pircey Enterprises to do the conversion as Ron is well versed in the installation process and uses only the best components. The first step is to remove the old rear suspension and related components.

The rear trunk area was then cut to accommodate the Art Morrison Narrowed 4-Link Rear Clip. The clip is then welded into position. These photos show the rear clip tacked in place along with the Main Hoop of the new 8 Point Roll Cage. The cage is made from 1 5/8 DOM tubing in accordance with NHRA requirements.

The cage is attached to both the rear clip and braced to the stock frame as well. The extra strength provided by the roll cage and bracing will prevent any flexing that was common with the non-reinforced stock chassis.

The next group of photos show the finished clip and roll cage after glossy black paint was applied.

Once the paint was dry, construction continued with the installation of the wider wheel tubs and rear tinwork.

Additional tin work in the center portion of the trunk and some assorted small tin pieces were fabricated to finish the flooring in the trunk area.

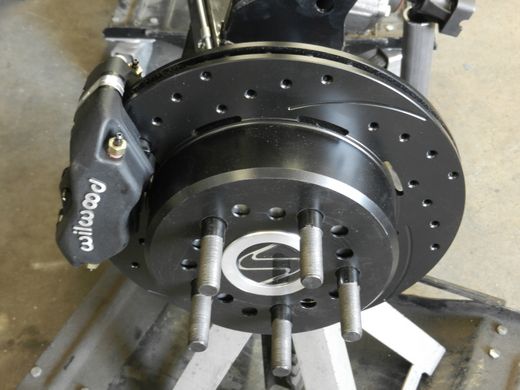

The fully assembled, custom fabricated rear end housing included state of the art Wilwood Rear Disk Brakes.

With construction nearing completion the next set of photos show different views of the finished product.

June 25th, 2013

June 25th, 2013  admin

admin