According to their official website; the Silver State Classic Challenge: “The State of Nevada closes down 90 miles of Route 318 and more than 200 drivers from around the world converge on the little town of Ely in the central high desert of Nevada. Why do they come? To experience first-hand the adrenaline rush of driving flat-out on a public highway. Not just professional racers, but men and women from all walks of life, pursuing the Walter Mitty dream of speed, horsepower, and high performance. Yes, there’s a place for everyone in the Silver State Classic Challenge”

One of those men is Ardin Scoggs, who’s weapon of “choice” is one of the best of the late model factory Hot Rods; in the form of a 2006 Pontiac GTO. From the factory the car is powered by a 6.0-liter V8 rated at 400 horsepower and 400 pound-feet of torque along with a limited-slip differential and traction control. Ardin, like many prefer the sounds and performance of the original “old school” Small Block Chevrolet. Although this car will use a highly modified; 358 C.I. Small Block backed by a Richmond 6 speed manual gearbox.

Because of the expected performance and high speeds associated with competition in “The Classic”; safety is a primary concern. To that end Ardin chose Ron Pircey Enterprises to install the proper roll cage, competition legal fuel cell and subframe connectors to tie everything together.

When the car came to Ron’s shop in Federal Way, the interior, engine and most of the wiring and dashboard components had been removed in preparation for installation of the safety components.

Subframe Connectors are used to literally “tie” the factory front and rear subframes together; substantially reinforcing the chassis. The stiffening that is provided by these connectors will improve the already great handling characteristics of the factory GTO.

The roll cage will provide additional stiffness and the obvious safety benefits. Notice the tight fit of the 1 5/8” DOM tubing as it is formed to fit the contours of the GTO and how it is “bent” to the accommodate the stock dash.

Proper mounting at the floor locations and additional bracing will do nothing but add even more stiffness.

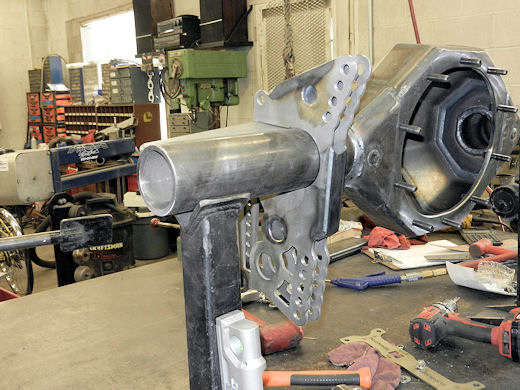

Mounting the racing fuel cell required the use of a steel plate “mounting ring” to meet the safety requirements and further stiffen the trunk area after the opening was cut for the cell.

Overall this was a great project and was a break from the street rod and drag racing projects that are obviously more common around here!

Lots of work lies ahead for Ardin and his crew as this the November deadline looms ahead…

Good luck to Ardin at “The Classic” for more information on this year’s 25th Anniversary Silver State Classic Challenge click on the link below:

April 5th, 2013

April 5th, 2013  admin

admin